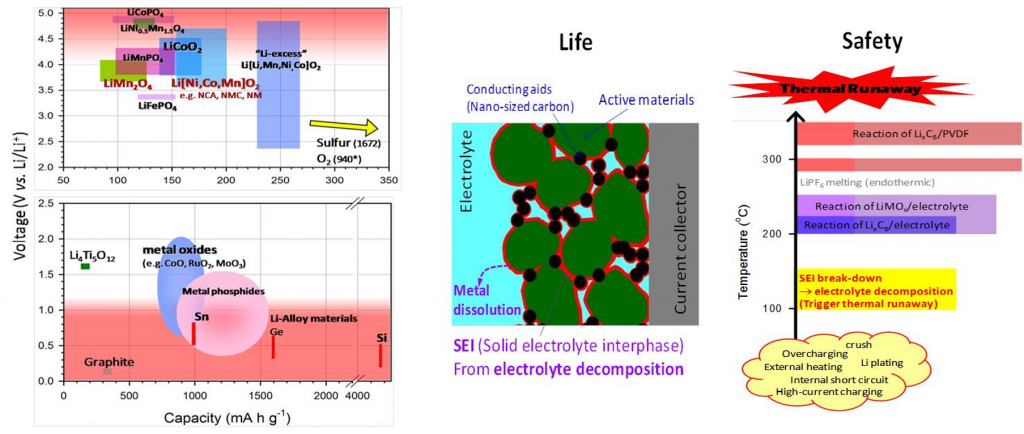

Despite their promise, problems with lithium-ion batteries (LIBs) such as life and safety issues have been bottlenecks for the introduction of these batteries in mass production of electric vehicles (EVs). Some of the degradation and capacity loss can be traced to corrosion of the electrodes due to electrode dissolution and reactions that occur between the electrodes and the surrounding electrolyte. Establishing long-term durability while operating at realistic temperatures for a battery that does not fail catastrophically remains a significant challenge.

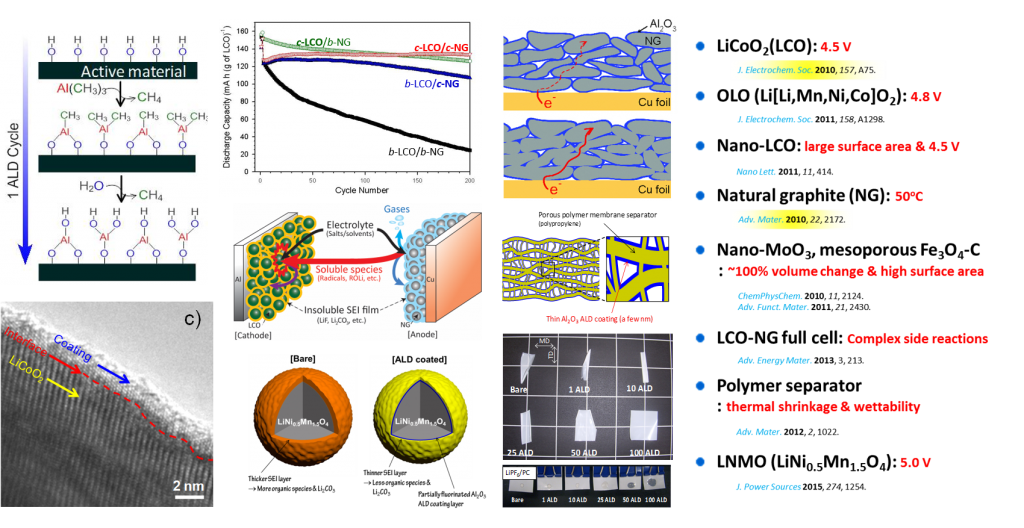

Atomic layer deposition (ALD) is a gas-phase method of thin-film growth using sequential, self-limiting surface reactions. ALD requires only a minimal amount of precursor, and ALD coatings are conformal and offer atomic thickness control. ALD can be also applied either on powders or on as-fabricated electrodes. The well-known ALD process utilizing trimethylaluminum (TMA) and H2O are

(A) AlOH* + Al(CH3)3 → AlO-Al(CH3)2* + CH4

(B) AlCH3* + H2O → Al-OH* + CH4

ALD was demonstrated to significantly improve the performance of cathode and anode for LIBs in terms of durability, rate capability, and safety. The improvements are explained by protective role of the ALD coatings against undesirable electrode-electrolyte side reactions and enhanced mechanical integrity.